Integrated Circuit Fabrication Process

Integrated Circuit Fabrication Process. In a monolithic IC, all the circuit components are fabricated into or top of a block of silicon which is The processing steps used to fabricate various silicon devices, such as diodes, transistors, and integrated circuits as follows Integrated circuit - Integrated circuit - Fabricating ICs: The substrate material, or base wafer, on which ICs are built is a semiconductor, such as silicon or gallium arsenide. All mainstream semiconductor integrated-circuit processes start with a thin slice of silicon, known as a substrate or wafer.

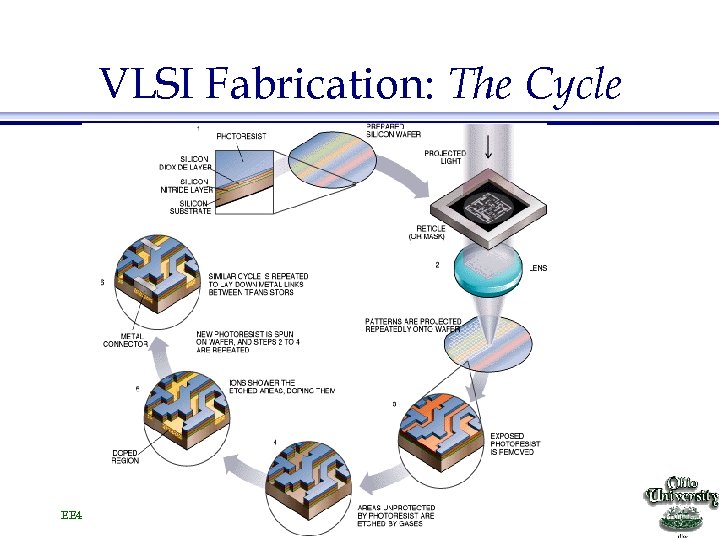

Process steps including: crystal growth, epitaxy, oxidation, ion implantation, etching, deposition, lithography and back-end processing.

A process flow is a sequence of instructions and steps that describe.

The fabrication of integrated circuits consists basically of the following process steps: Lithography: The process for pattern definition by applying thin uniform layer of viscous liquid (photo-resist) on the wafer surface. Notes on Integrated Circuit Fabrication Process which will cover the topics such as Introduction, Fabrication Steps, Fabrication Process and Twin Tub CMOS A monolithic IC consists of active and passive components formed by diffusion into a single silicon chip, with interconnection provided by an. ICs are also classified based on the fabrication process and packing technology.