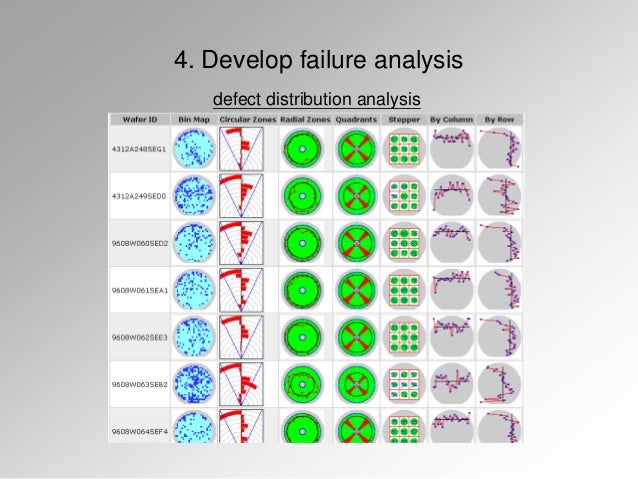

Integrated Circuit Failure Analysis

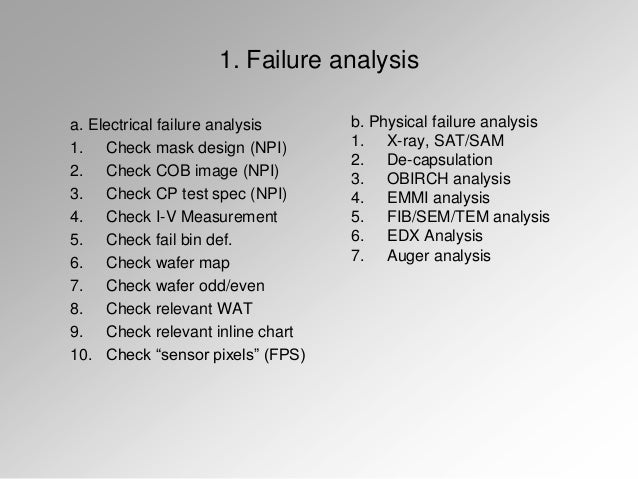

Integrated Circuit Failure Analysis. The research of failure analysis for integrated circuits can improve the reliability. In order to ensure planarity while conducting sequential intergarted circuites (IC) delayering, it is preferred that each dielectric etch is stopped when a specific level is attained, which is uniform with the next metal layer that needs to be etched.

This "must have" reference work for semiconductor professionals and researchers provides a basic understanding of how the most commonly used tools and techniques in silicon-based semiconductors are applied to understanding the root cause of electrical failures in integrated circuits.

Integrated Circuit Failure Analysis describes state-of-the-art procedures for exposing suspected failure sites in semiconductor devices.

Welcome to the Semiconductor and Electronics Failure Analysis Blog, and discussion forum for all things related to electrical, integrated circuit (IC) board and electronics failure analysis. Since this analysis method is for integrated circuits, they can be replaced on the assembly, but they themselves are non-repairable circuitry. Integrated Circuit Failure Analysis: A Guide to Preparation Techniques.